Noises originating from artificial hip replacements:

Where do they come from and how can they be prevented?

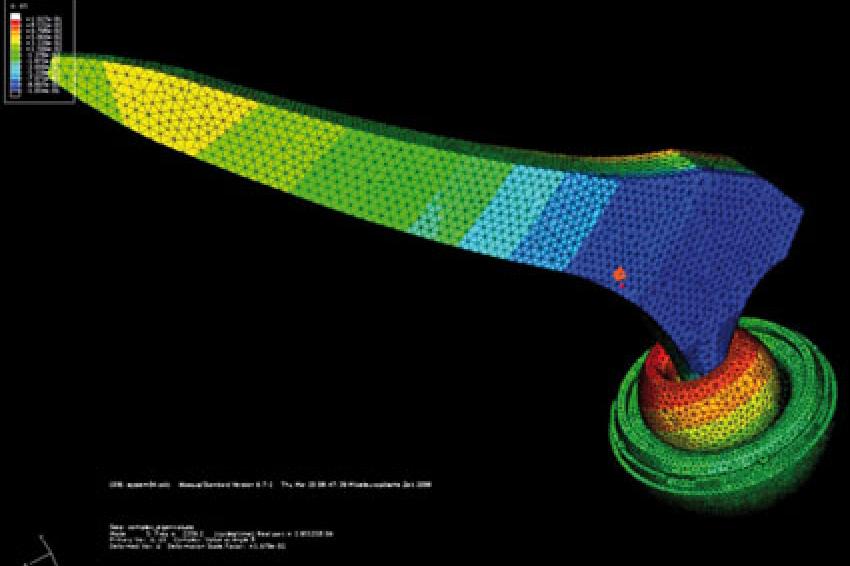

From a technical point of view, two types of noises should be differentiated since they originate from two different mechanisms: squeaking (tonal sounds) and clicking (transient noise). All the different terms used can (and should) be assigned to one of these two types. Squeaking noises are caused by friction induced vibrations of the whole prosthesis system (Figure 1). A pre-requisite for this to occur is high friction in the joint articulation. The frequency of the resulting sound is influenced heavily by the natural frequency of the stem [2]. Clicking noises are resulting from short and "hard" contact events occurring after sub-luxation when the head locates back into the cup or during impingement.

Theoretically all bearings couples can be involved, when either the friction in the articulation is high enough or two hard components of the prosthesis system get "hard" in contact. Practically, however, noises are observed nearly exclusively in hard-on-hard articulations namely Metal-on-Metal or Ceramic-on-Ceramic bearings. The superior wear characteristics of these bearing materials are due to their ability to achieve fluid film lubrication during movement, effectively separating the bearing surfaces and such reducing wear and friction. If the fluid film breaks down, the advantage of hydro-dynamic lubrication is completely lost and turns into a situation with high friction and high wear. This can be easily imagined thinking of a car engine without oil. Hard-on-soft bearings with polyethylene always operate in the boundary lubrication mode (the surfaces are in contact) due to the bad wetability of the material. This makes them rather insensitive with respect to the presence or absence of fluid.

Major factors for the occurrence of noise phenomena

The patient him- or herself has nearly no influence on the occurrence of the noise phenomenon. Large utilized ranges of joint motion and/or high body weight can be minor factors due to their association with cup edge loading or higher wear [4]. The major factors, however, are prosthesis design and the surgical procedure, especially their aspects, which have the potential to increase friction [2,4,5]. Friction is increased mostly due to edge loading, metal transfer (probably caused by impingement or subluxation; Figure 2), mismatched materials, combination of wrong sizes (Figure 3) or third body particles. Edge loading and metal transfer cause a breakdown of the fluid film with the consequences mentioned. Both are related to component position, which is probably THE most important single factor for the frequency of noises with total hip arthroplasty (THA). In some designs the positioning of the components is even more critical due to certain design features. The majority of the squeaking events have been reported for one particular THA design using a titanium alloy with a lower stiffness than usual [3]. In this system, the rim of the ceramic liner is protected by a metal sleeve, facilitating metal transfer to the head, which could also cause a higher frequency of squeaking occurrence then in other designs.

Frequency of noise observation

The frequency of noise observation depends interestingly very much on the heritage of bearing materials used. In countries, in which ceramic articulations have been used for long times (e.g. France, Germany, Italy), squeaking of THA is rather an anecdotal event, probably since the surgeons are aware of the overwhelming importance of component positioning. In countries, in which ceramics have been introduced recently and historically forgiving hard-soft bearings were used, the rates reported are higher, which might also partly be due to the use of the particular THA system mentioned. Furthermore, the local legal situation might also influence the situation. Realistically the squeaking frequency of ceramic-on-ceramic articulations in these regions probably lies between 1% and 3%. Squeaking of metal-on-metal articulation has also been reported frequently. However, this squeaking goes away as the articulation has the ability to wear, such increase the contact surface and decrease friction. The resulting large amount of metal debris, however, can lead to biological reactions. Since ceramic does not wear easily, the noise phenomenon is usually persistent.

Joint noises can serve as a diagnostic help since they are an indication that the tribological situation in the joint is not as desired. The surgeon should carefully evaluate the joint functionally and radiologically in order to identify the source of the problem such as extensive cup anteversion, joint laxity or impingement. In this context it should also be carefully determined, how frequent this complication occurs. If the occurrence is rather rare (for example "only after 3 hours of walking uphill"), the phenomenon might not have a prognostic significance. If the phenomenon occurs regularly during daily activities (e.g. stair climbing, lifting objects), the surgeon should probably use the opportunity to change the mechanical situation in the joint before something worse than a noise phenomenon occurs. Especially repetitive clicking noises are an indication for hard contacts in small areas resulting in high stresses in the material.

The materials in joint replacement available today include high performance materials, quite comparable to the materials used in Formula I racing. Everybody accepts that highest performance in racing always comes for the price of reduced tolerance to errors. The same is true in hip arthroplasty. The engineers will continue to try to make the materials more forgiving for suboptimal handling and positioning, which will probably be only successful within certain limits. The general rule "high performance comes with little error tolerance" will remain in the foreseeable future. Several promising bearing combinations are available for young and active patients which even have the potential to last for a life time. There are three aspects, which should be considered: (1) bearing materials operating in the boundary lubrication mode do wear - they might last for a very long time but at one time they will be worn sufficiently to need revision either due to aseptic osteolysis or dislocation; (2) activities which have a higher risk for injury do not become less dangerous for a patient with an artificial hip joint; (3) bearings which are more sensitive to handling and positioning deviations should only be used by surgeons with the required qualifications.

References

- Glaser D, Komistek RD, Cates HE, Mahfouz MR. Clicking and squeaking: in vivo correlation of sound and separation for different bearing surfaces. J Bone Joint Surg Am 2008; 90 Suppl 4 112-20

- Hothan A, Huber G, Weiss C, et al. The influence of component design, bearing clearance and axial load on the squeaking characteristics of ceramic hip articulations. J Biomech 2011; 44 837-41

- Stanat SJ, Capozzi JD. Squeaking in Third- and Fourth-Generation Ceramic-on-Ceramic Total Hip Arthroplasty Meta-Analysis and Systematic Review. J Arthroplasty 2011;

- Walter WL, O‘toole GC, Walter WK, et al. Squeaking in ceramic-on-ceramic hips: the importance of acetabular component orientation. J Arthroplasty 2007; 22 496-503

- Weiss C, Gdaniec P, Hoffmann NP, et al. Squeak in hip endoprosthesis systems: An experimental study and a numerical technique to analyze design variants. Med Eng Phys 2010; 32 604-9.

Kontakt

Hamburg University of Technology

Denickestr. 15

21073 Hamburg

Deutschland

+49 40 42878 0

+49 40 42878 2288